One of the outcomes I found most encouraging from the recent COP26 (United Nations Climate Change Conference) in Glasgow was the announcement of new efforts that will work to slash carbon emissions from industries that have been historically difficult to decarbonize.

Such work is essential because while the world has made tremendous progress toward developing and deploying renewable energy technologies that can power our economy, those methods alone can’t reduce greenhouse gas emissions enough to save us from the worst impacts of climate change.

When I say, “We’ve got to decarbonize everything,” that includes the petrochemicals that are primary inputs for so many products we use every day and will continue to use in a decarbonized economy. Petrochemicals will likely continue to be used in some way, shape, or form for generations. That’s why it makes sense for us to squeeze as much carbon out of this sector as possible.

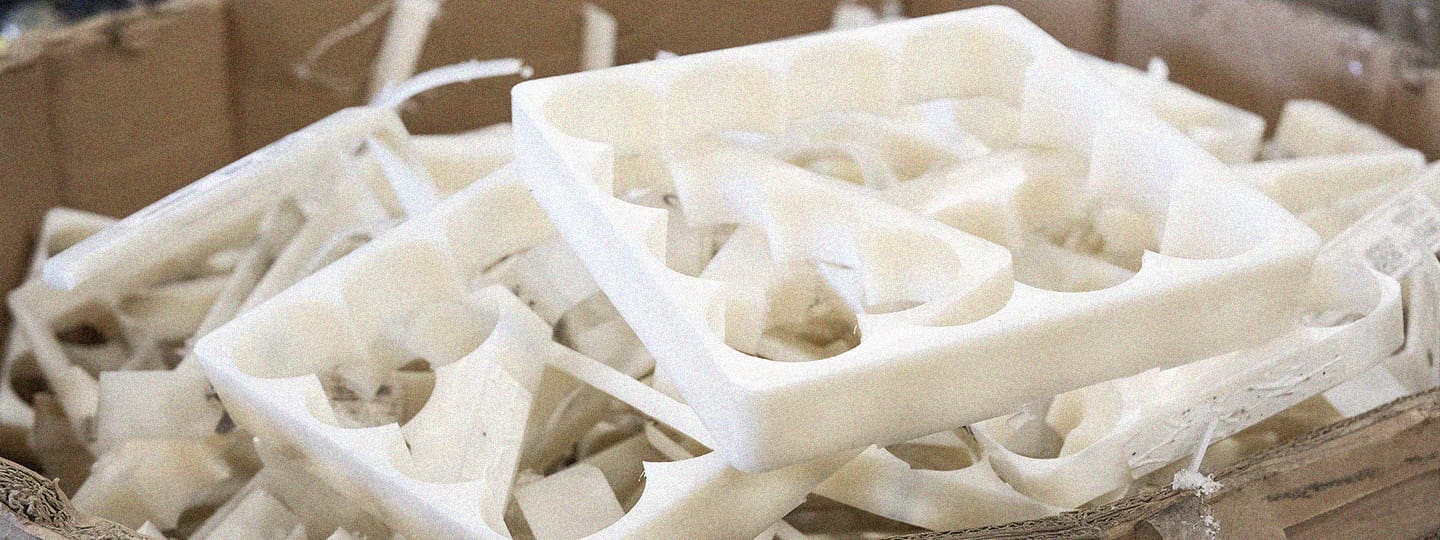

Now, a new peer-reviewed analysis has demonstrated how Brightmark’s plastics renewal technology processes help decarbonize petrochemicals, even as we continue to strive for the development of fully circular plastics. Our team commissioned the Georgia Institute of Technology and Environmental Clarity, Inc. to conduct a complete peer-reviewed lifecycle analysis of our proprietary, pyrolysis-based plastics renewal technology. The study revealed that the plastics renewal process produces 39%-139% fewer greenhouse gas emissions than equivalent products made from virgin materials.

Our technology’s carbon footprint benefit is further affected by how much incineration is used for waste disposal in a given region. For example, in Europe, where 50% of plastics are incinerated, Brightmark’s plastics renewal’s carbon footprint improvement jumps to 139% compared to equivalent virgin products. That’s one reason why we recently announced an exploratory effort to deploy our technology in communities in Germany, the Netherlands, and Belgium.

The report also finds that plastic renewal provides 82% energy use savings and 46% water use savings. In other words, products created by plastics renewal require 17% usage of fossil fuels and only 54% usage of water—which is much less than if the same products were made from virgin petroleum. These are tremendous savings, and we are very proud of the Brightmark team for accomplishing this impeccable milestone.

Much of what is proven by this analysis confirms what common sense tells us is that plastics renewal is a world-changing technology. It keeps our natural resources in use via the circular economy, provides a productive use for materials that would otherwise be landfilled, littered, or incinerated, reduces our need for new fossil fuel extraction, and slashes climate change emissions—all at once.

We support humanity’s shared mission to decarbonize everything. Join us on our mission to Reimagine Waste.